The Real Metaverse: Your 2025 Guide to the Industrial Worlds Being Built Today

Man, remember that wild metaverse frenzy? Feels like yesterday—2022, everyone was losing their minds over pixel people and digital real estate. Tech bros flexing their virtual cribs, pretending those floating torsos in VR meetings were the future (seriously, what was up with the no legs?). Then—bam!—the hype nosedived. Suddenly, all the headlines screamed, “Welp, Metaverse Is Dead!” and the same folks ghosted.

Alright, plot twist: the metaverse didn’t just peace out. It stopped screaming “BUY THESE NFT SUNGLASSES!” every five seconds and, get this, started actually doing cool, useful stuff. Welcome to the Industrial Metaverse—basically the grown-up, no-nonsense version where digital worlds finally pull their weight. Now we’re talking Embodied AIZ, OpenUSD, and AI Agents showing up to wrestle with trillion-dollar messes in places like factories, warehouses, and design studios. No crypto clowns in sight.

This guide? Call it your backstage pass, no velvet rope. I’m not here to sell you magic beans. Instead, you’re getting the real inside scoop—straight from BMW, Siemens, and Amazon. We’ll pop the hood and see why the Industrial Metaverse is about to flip everything you thought you knew about work, design, and automation on its head. Buckle up.

Wait, Industrial Metaverse? What Even Is That?

Let’s ditch the Roblox and Fortnite chatter right now. This isn’t about pixelated dance battles. The Industrial Metaverse basically builds a digital clone of real stuff—factories, supply chains, heck, sometimes whole cities. But don’t get it twisted; it’s not for play. It’s here to solve real problems, not rack up high scores.

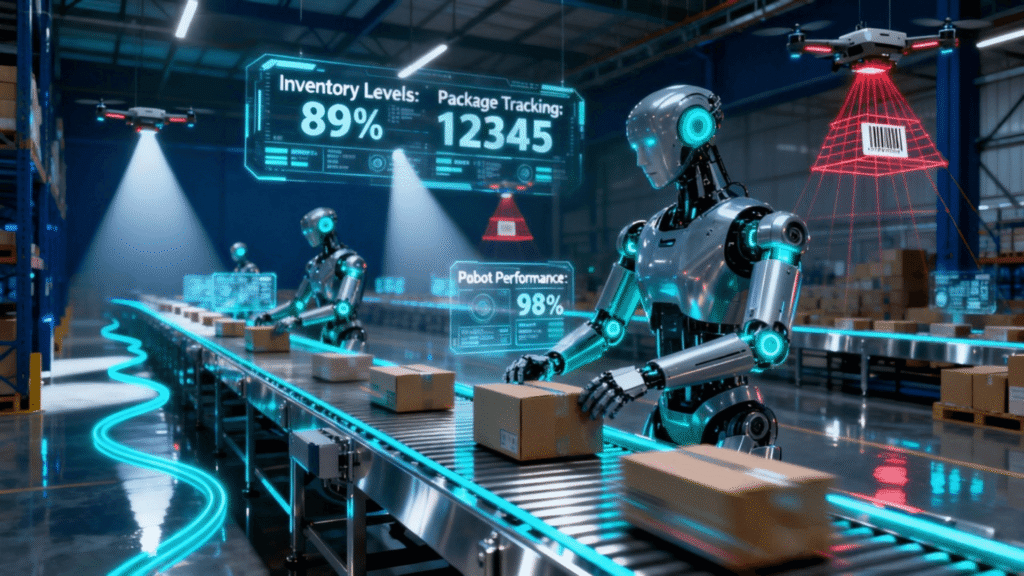

Thousands of sensors beam data into live digital models. Every conveyor belt, robot arm, and machine beep is synchronized in real time. Inside this digital playground, AI Agents run millions of “what-if” scenarios—optimizing workflow, predicting failures, and improving efficiency—without touching a single real-world object.

| Old Consumer Metaverse (Hype) | Industrial Metaverse (Reality) |

|---|---|

| Social hangouts, games, avatars | Hard-hitting simulations, robotics |

| Escapism—virtual worlds | Fixing this world with digital twins |

| Meta, Roblox, etc. | NVIDIA, Siemens, Microsoft, BMW |

The Building Blocks: What’s Under the Hood of the Industrial Metaverse?

The Industrial Metaverse is powered by a fusion of four tech superpowers:

Digital Twins: The Backbone

Ditch the whole “static 3D model” idea. Digital twins? They’re like digital doppelgängers—always alive, always in sync, sucking in fresh data every second. They’re not just chilling there. They’re tracking every hiccup and heartbeat of a machine, calling out when something’s about to blow, and letting engineers mess around with “what ifs” before anyone’s wallet (or pride) takes a hit.

OpenUSD: The Universal Translator for Machines

Okay, so you ever tried making a Siemens CAD program chat with a KUKA robot, while an NVIDIA sim engine eavesdrops? Yeah, good luck with that mess. Enter OpenUSD: basically the Rosetta Stone for 3D stuff. Imagine if HTML and Lego had a baby for machines—now everything from digital twins to robots to AI agents can stop arguing and just get stuff done. No more tech tantrums, just smooth, nerdy harmony.

AI and Simulation: The Brains of the Operation

Amazon’s warehouses use digital twins to simulate humanoid robots and workflow optimizations. It’s like The Sims, but everyone is a robot or a package. Testing ideas virtually shaves milliseconds per action, which scales to huge efficiency gains.

IoT and Real-Time Data: The Nerve Center

Honestly, IoT sensors are like the nerves in your body—they’re the reason your digital twin isn’t just some lifeless 3D model collecting dust. These little gadgets pick up everything: heat, pressure, location, you name it. No sensors? Your digital twin’s basically a screensaver. With sensors, though, your virtual world actually keeps up with the real one. Wild, right?

Case Studies: The Industrial Metaverse in Action

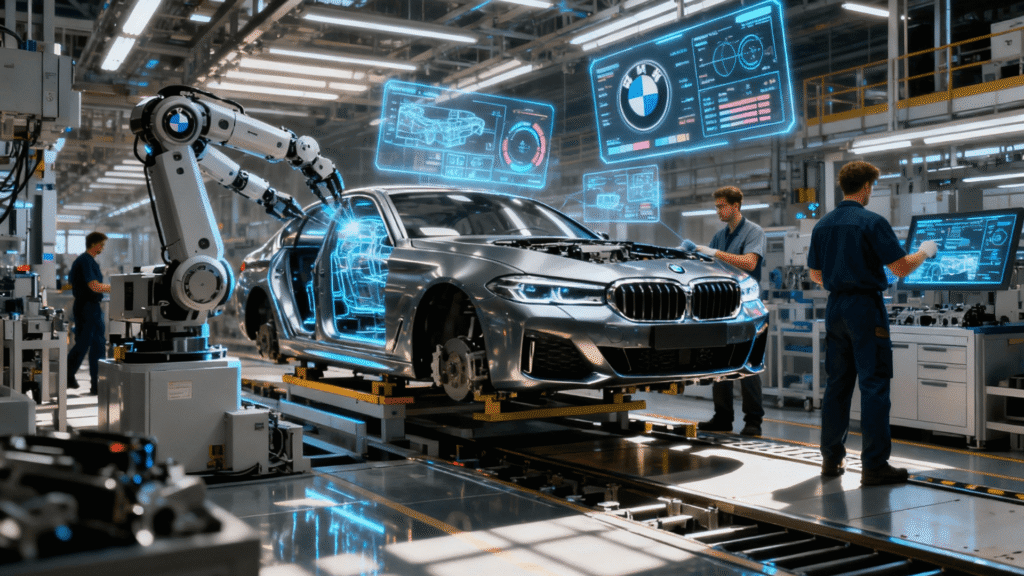

Case Study 1: BMW & NVIDIA Omniverse

BMW built a full digital twin of its EV plant in NVIDIA Omniverse. Every robot, conveyor belt, and even human activity is mapped. Engineers tested workflows virtually before breaking ground—avoiding bottlenecks and saving millions of dollars and months of time.

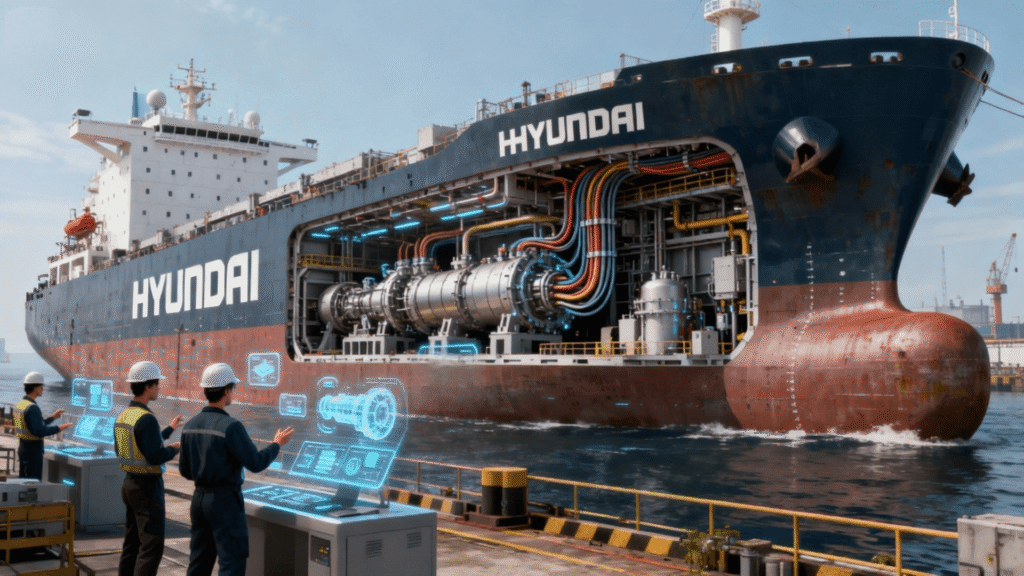

Case Study 2: Siemens & HD Hyundai

Constructing an LNG carrier? Insane complexity. Siemens software lets HD Hyundai create a digital twin of the entire ship. Engineers from every department—hull, electrics, plumbing—collaborate virtually, spotting design mistakes before they cost millions.

Case Study 3: Amazon Robotics

Amazon runs a digital replica of warehouses. AI agents test new humanoid robots and workflow tweaks in a virtual environment, optimizing every second of operations.

Peeking Ahead: How the Industrial Metaverse Will Disrupt Everything

The Resilient Supply Chain

Disasters happen—warehouses catch fire, cargo ships get stuck—but digital twins let companies simulate responses instantly, minimizing downtime and losses.

The Evolution of Jobs

New roles emerge: Digital Twin Manager, Robot Simulation Specialist, AI Workflow Optimizer. It’s not about robots stealing jobs; it’s about humans collaborating with AI to manage smarter, faster systems.

Conclusion: The Metaverse That Actually Matters

Forget cartoon avatars and VR beach parties. The Industrial Metaverse is a digital twin of reality, empowering humans and AI to control, optimize, and innovate. Humanoid robots, AI agents, and OpenUSD combine into a platform with real-world impact.

Expanded FAQ

Want weekly AI & Robotics briefings?

Subscribe and get a one-page “Robotics 2025 Cheat Sheet” when you join.

Newsletter coming soon!